69 Norman St.

Everett, MA 02149

Phone: 617-389-8440

Fax: 617-389-2831

69 Norman St.

Everett, MA 02149

Phone: 617-389-8440

Fax: 617-389-2831

Since our founding in 1890, we have maintained a focus on providing Hot Dip Galvanizing as the most cost effective, longest lasting solution to corrosion.

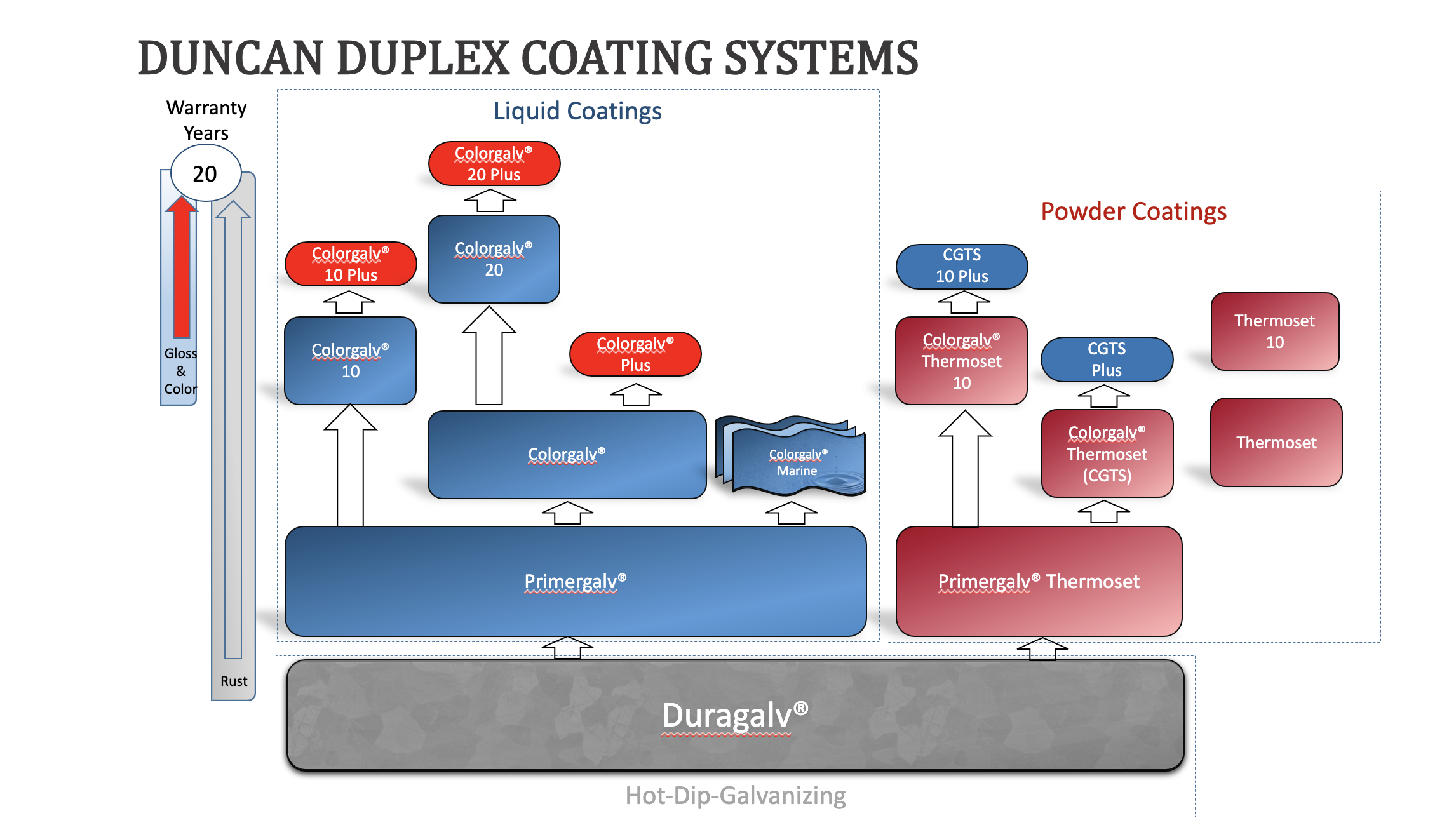

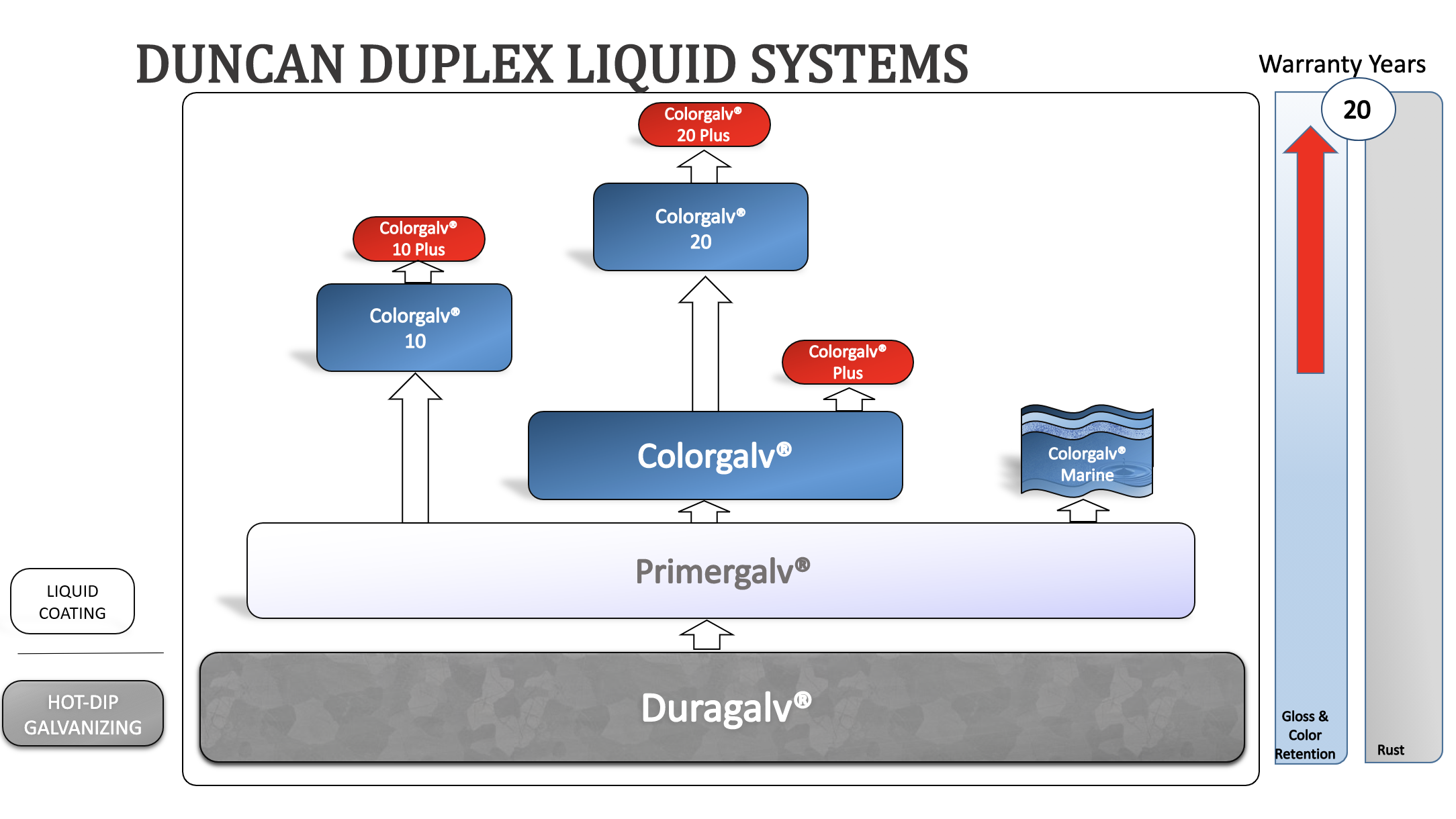

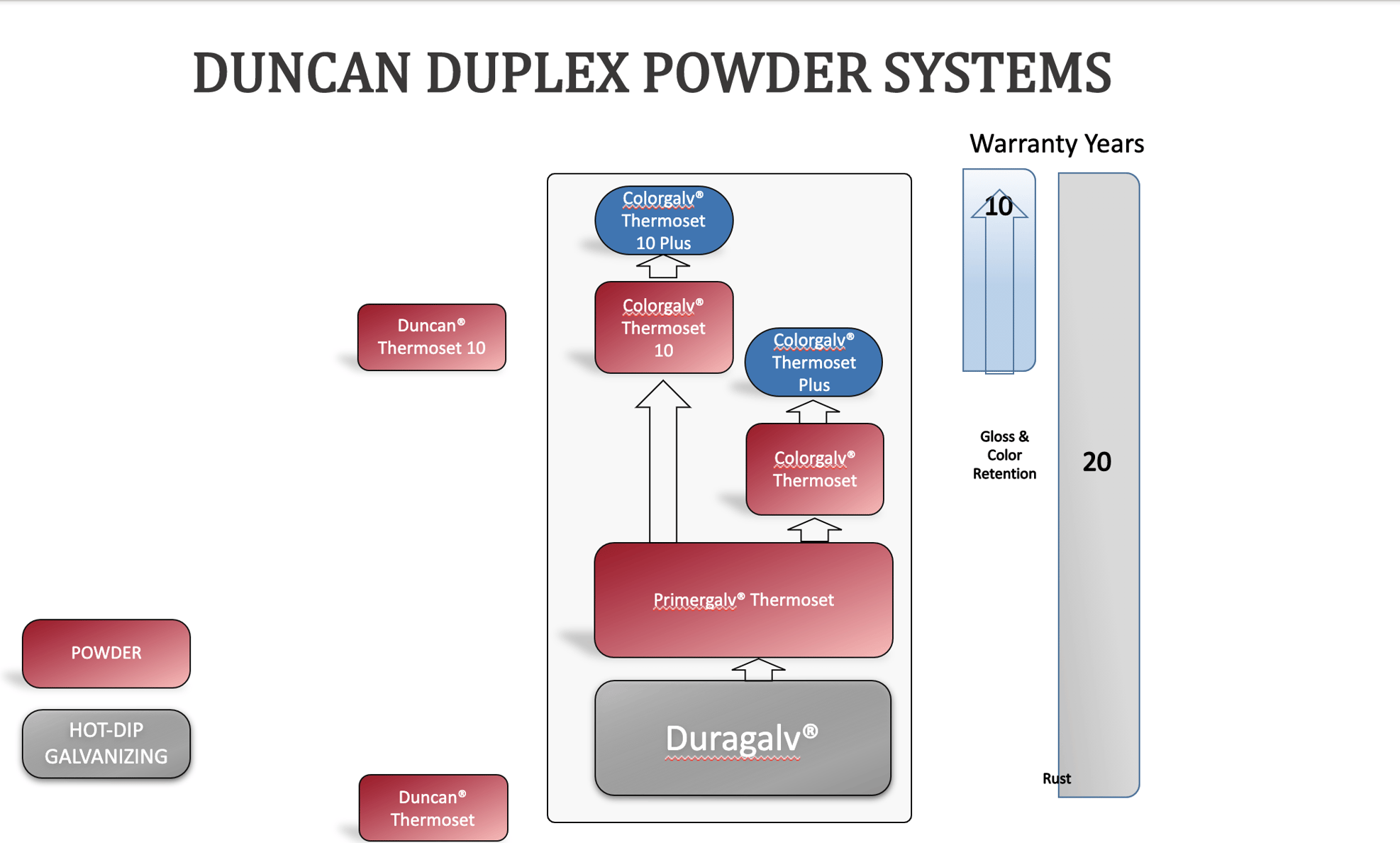

In keeping with that focus, all Duncan’s value added processes utilize Hot Dip Galvanizing as a base.

Duncan Galvanizing has been providing state-of-the-art Hot Dip Galvanizing for over 130 years. Our Duplex Coating Systems have been the industry standard for over 45 years. High Performance Industrial Coatings combined with our Hot-Dip Galvanizing provide proven performance that will last decades.

Learn about Duncan's different specifications below. Click on the link to download.

Duncan Galvanizing, Corp. 69 Norman Street, Everett, MA 02149 Phone: 617-389-8440

© 2018 Duncan Galvanizing, Corp. All Rights Reserved Privacy Policy Site Map